Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-07-10

Introduction:

The mining industry plays a crucial role in the extraction of natural resources, including granite. Granite chain saw machines are essential tools used in the mining process to cut and shape granite blocks into usable forms. Understanding the product knowledge of these machines is vital for operators to ensure efficient and safe operations. This article aims to provide an overview of the essential product knowledge required for operating granite chain saw machines.

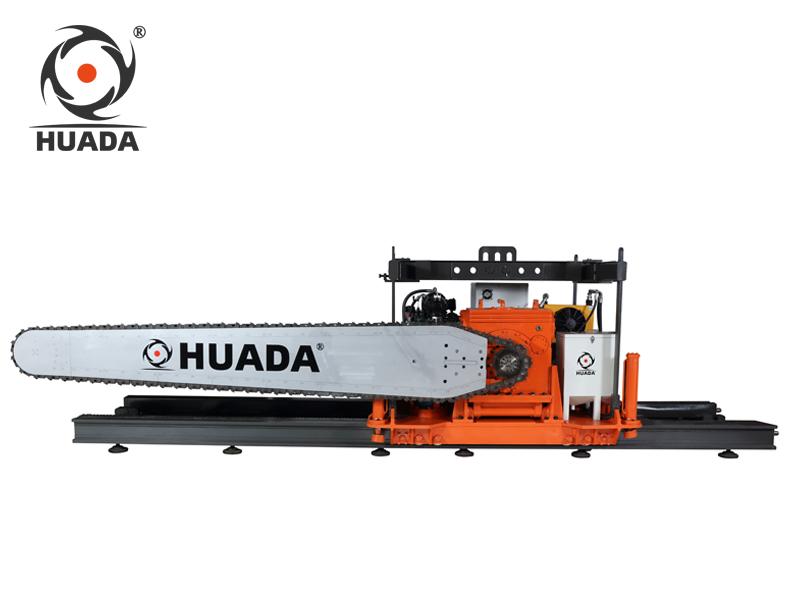

Granite chain saw machines consist of various components that work together to facilitate the cutting and shaping of granite blocks. The primary features of these machines include:

- Saw Bar: This is the main cutting tool attached to the machine, usually made of high-quality steel. It is responsible for cutting through the granite blocks.

- Cutting Chain: The saw bar is equipped with a durable cutting chain with sharp teeth, specifically designed for cutting through hard materials like granite.

- Motor and Power Source: Granite chain saw machines are powered by either gasoline or electricity. Gasoline-powered machines offer more mobility, while electric machines provide consistent power supply and lower emissions.

- Guide Bar and Chain Lubrication: To ensure smooth operation and minimize friction, the guide bar and cutting chain require regular lubrication. Proper lubrication reduces wear and tear and extends the lifespan of the machine.

Operating granite chain saw machines involves inherent risks, and it is crucial to prioritize safety. Here are some essential safety precautions to follow:

- Personal Protective Equipment (PPE): Operators must wear appropriate PPE, including safety goggles, gloves, helmets, and ear protection, to safeguard themselves from potential hazards.

- Machine Inspection and Maintenance: Regular inspections of the machine are necessary to identify any faults or damages. Maintenance tasks, such as chain tension adjustment and lubrication, should be performed according to the manufacturer's guidelines.

- Proper Training: Operators must undergo thorough training to develop the necessary skills and knowledge for operating granite chain saw machines safely. Training programs should cover machine operation, maintenance, and emergency procedures.

- Worksite Safety: Adequate safety measures, such as clear signage, barriers, and warning systems, should be implemented at mining sites to prevent accidents and injuries. Operators should also be aware of their surroundings and communicate effectively with coworkers.

To achieve efficient and precise cutting of granite blocks, operators should employ the following operational techniques:

- Positioning and Blocking: Proper positioning of the machine and the granite block is crucial for accurate cutting. The block should be securely blocked to prevent movement during the cutting process.

- Cutting Speed and Pressure: Operators must maintain an appropriate cutting speed and apply sufficient pressure on the saw bar while cutting through the granite. This ensures smooth and consistent cutting without damaging the machine.

- Cooling and Water Supply: Continuous cooling of the cutting chain is necessary to prevent overheating. Water supply systems should be set up to provide adequate cooling and eliminate dust produced during the cutting process.

- Waste Management: Proper disposal of waste materials, such as granite debris and used cutting chains, should be practiced to maintain a clean and safe worksite. Recycling and reusing waste materials whenever possible is also encouraged.

Conclusion:

Having a comprehensive understanding of the essential product knowledge for granite chain saw machines is vital for operators in the mining industry. Proper knowledge of machine components, adherence to safety precautions, and implementation of effective operational techniques ensure not only efficient operations but also the safety and well-being of the operators. By prioritizing product knowledge and safety, the mining industry can maximize productivity while minimizing risks.