Introduction:Italian Craftsmanship – Setting New Standards in Stone Wire Saw Quality

Price:

+8619859567581

Precision Press-Down Cutting for Ultra-Thin Materials

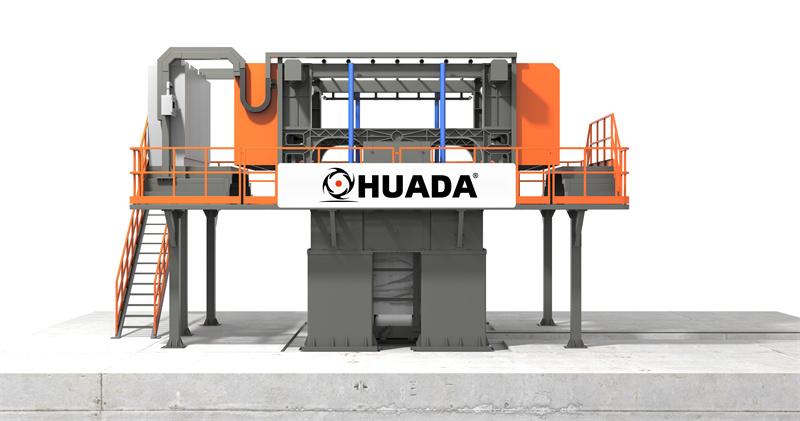

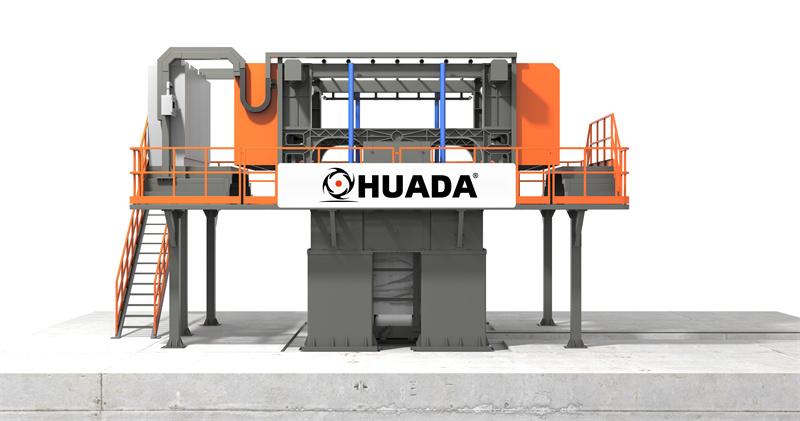

Co-developed by Huada and Gaspari, the machine adopts a four-pillar internal structure meticulously refined through Finite Element Analysis (FEA). This ensures outstanding rigidity and vibration resistance, even during high-speed slicing of ultra-thin materials.

To prevent internal deformation over time, machine castings undergo an 8-day+ thermal stress-relief cycle. A PID-controlled furnace maintains precise temperature control, with a gradual cooling rate of 20℃ per hour to eliminate residual thermal stress.

All bearing housings are ground using single-clamp precision grinding in a temperature- and humidity-controlled environment. Each unit passes through an 18-step quality assurance process, ensuring ultra-high geometric accuracy and consistent long-term performance.

Incorporates a synchronized constant-torque algorithm across four rollers. This solves common issues such as wire breakage in legacy systems and dramatically improves cutting stability and system durability under continuous operation.

Equipped with an intelligent, real-time wire tension monitoring and prediction system. This AI-driven module dynamically adjusts to fluctuations, achieving superior wire tension stability and reducing material loss.

Engineered specifically for cutting ultra-thin materials such as sapphire, quartz, silicon, and specialty ceramics. The machine ensures high precision, minimal kerf loss, and mirror-smooth finishes—ideal for photovoltaic, semiconductor, and optical industries.

Smart layout and modular design simplify maintenance and reduce downtime. Key components are easily accessible, and diagnostic systems provide early warnings for wear or failure.

|

Machine length |

11000mm |

|

Machine width |

7000mm |

|

Maximum height |

6500mm |

|

Cutting length |

3700mm |

|

Cutting height |

2200mm |

|

Cutting width |

2200mm |

|

Max power of the main motor |

64KWx4=256kW |

|

Total installed power |

300kW |

|

Linear speed |

35m/s |

|

Rising speed |

0-420mm/min |

|

Block dimension |

3500x2200mm |

Precision Multiwire Cutting for Ultra-Thin, Hard Materials 1. Dual-Axis Motion: Lifting and Swinging Integration This advanced multiwire saw features a fully integrated lifting ...

Precision Press-Down Cutting for Ultra-Thin Materials 1. High-Rigidity Press-Down Structure for Ultra-Stable Cutting The core of the machine features a high-strength press-down fra...

1. Ultra-Rigid FEA-Optimized Structure Co-developed by Huada and Gaspari, the machine adopts a four-pillar internal structure meticulously refined through Finite Element Analysis (FEA...

The Satisfaction Of Our Customers Is Our Motivation!

Learn more about stone cutting machine!

10

2025-07

26

2025-01

25

2025-01

24

2025-01

23

2025-01

Please Fill In The Correct Tel & E-mail,

We'll Contact You As Soon As Possible!