Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-08-07

Quarry Wire Saw Machine Maintenance Guide

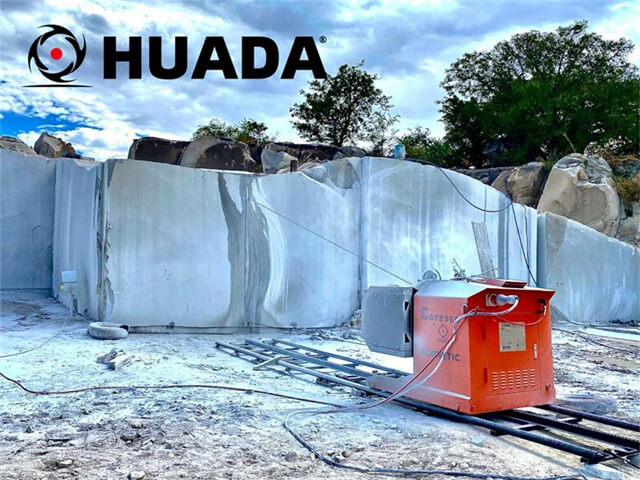

Quarry wire saw machines are essential tools in the process of stone extraction. They are used to cut through large blocks of stone with precision and efficiency. To ensure the longevity and optimal performance of these machines, proper maintenance is crucial. This guide provides a comprehensive overview of the maintenance procedures for quarry wire saw machines.

Regular cleaning and inspection play a vital role in maintaining the efficiency of quarry wire saw machines. After each use, it is important to clean the machine thoroughly. Use compressed air to remove any dust, debris, or sludge from the wire saw. Inspect the wires carefully for any signs of wear, such as fraying or distortion. Replace worn-out wires promptly to prevent accidents or damage to the machine.

Additionally, inspect the guide wheels, pulleys, and bearings for any signs of damage or excessive wear. Lubricate these components regularly to ensure smooth operation. Pay special attention to the tension of the wire; it should be properly adjusted to avoid unnecessary strain on the machine.

The proper alignment of the wire saw is crucial for its efficient operation. Misalignment can lead to uneven cuts, reduced productivity, and increased risk of accidents. To align the wire saw correctly, start by checking the tension and tracking of the wire. Make necessary adjustments using the tensioning mechanism provided by the machine's manufacturer.

Next, verify the parallelism of the wire saw with the cutting surface. Adjust the guide wheels and pulleys accordingly to ensure that the wire follows a straight and consistent path during cutting. Regularly measure the cut thickness to confirm the accuracy of the alignment.

The electrical and mechanical components of quarry wire saw machines require regular maintenance to ensure their optimal performance. Inspect the control panel, switches, and wiring for any signs of wear or damage. Replace faulty components and repair any loose connections promptly.

Check the hydraulic system for leaks, and make sure the pump and other hydraulic components are properly lubricated. Regularly inspect the coolant system and clean or replace filters as necessary to prevent overheating. Keep the machine's motor clean, and monitor its performance to identify any irregularities.

In conclusion, maintaining a quarry wire saw machine is crucial for its longevity and optimal performance. Regular cleaning and inspection, proper alignment, and maintenance of electrical and mechanical components are key to ensure the efficiency and safety of the machine. By following this maintenance guide, quarry operators can maximize the lifespan of their wire saw machines and enhance productivity in the stone extraction process.