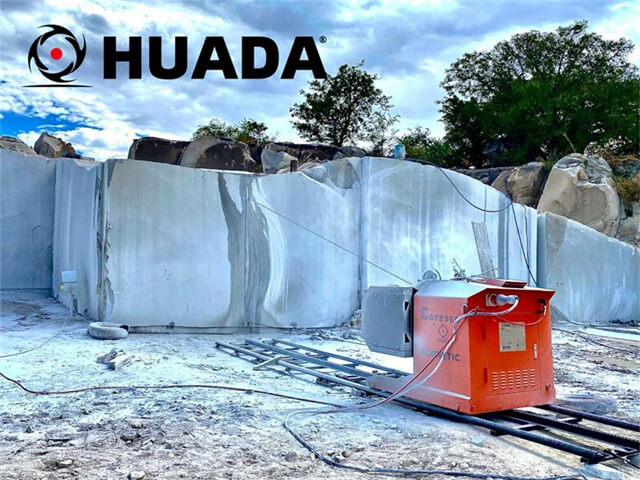

Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-08-04

Marble wire saw machine is a crucial tool used in the mining and extraction of stone materials such as marble. Regular maintenance of this machine is essential to ensure its efficient and safe operation. In this guide, we will discuss some important maintenance practices for marble wire saw machines.

Regular cleaning and lubrication are vital to maintaining the performance and longevity of the marble wire saw machine. After each use, make sure to clean the machine thoroughly, removing any debris or residue from the cutting area. Use a soft brush or compressed air to remove dust and particles that may accumulate in the machine's components. Additionally, lubricate the moving parts of the machine using suitable lubricants to reduce friction and prevent excessive wear.

Periodically inspect the various components of the marble wire saw machine to identify any signs of wear or damage. Check the wire saw blades, tensioning system, and hydraulic components for any cracks, breaks, or loose connections. If any damaged or worn-out parts are detected, replace them immediately to avoid compromising the machine's performance and safety. It is recommended to consult the manufacturer's guidelines or seek professional assistance for proper inspection and replacement procedures.

Proper calibration and alignment are essential for the accurate and precise cutting of marble using the wire saw machine. It is advisable to check and adjust the tension of the wire at regular intervals to ensure consistent and optimum cutting performance. Moreover, verify the alignment of the wire saw guide rollers and the tracking system to guarantee smooth movement and stability during the cutting process. Any misalignment should be corrected promptly to maintain the quality of the cut and prevent potential damage to the machine.

In conclusion, regular maintenance of the marble wire saw machine is fundamental for its efficient operation and longevity. Cleaning and lubrication, inspection and replacement of components, as well as calibration and alignment, are key practices to keep the machine in optimal condition. Adhering to these maintenance guidelines will not only enhance the machine's performance but also ensure the safety of operators. Remember to follow the manufacturer's instructions and consult professionals whenever necessary to guarantee proper maintenance procedures.