Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-07-28

Essential Product Knowledge for Stone Cutting Wire Saw Machine

Stone cutting wire saw machines are essential tools used in the mining industry for extracting stone blocks from quarries. These powerful machines utilize a diamond wire to slice through various types of stone, such as marble, granite, and limestone. To ensure efficient and safe operation, it is important to have a comprehensive understanding of the machine's essential product knowledge. This article provides an overview of the key aspects of stone cutting wire saw machines.

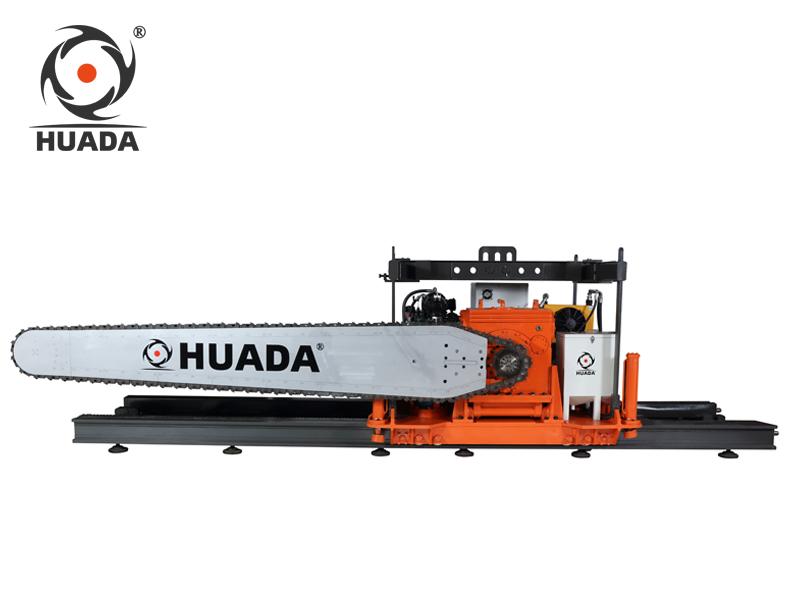

A stone cutting wire saw machine consists of several components that work together to achieve precise cutting. The main components include the wire saw assembly, power unit, control panel, and supporting structure. The wire saw assembly comprises a steel frame, a motorized flywheel, and a diamond wire coated with abrasive material. The power unit provides the necessary energy to operate the machine, while the control panel allows the operator to regulate the cutting speed and wire tension. The supporting structure ensures stability during cutting operations.

The working principle of a stone cutting wire saw machine involves the rotation of the diamond wire around the stone block. As the wire moves back and forth, it gradually cuts through the stone, resulting in a clean and precise cut. The machine's advanced technology enables operators to cut stones in various sizes and shapes, contributing to the versatility and efficiency of the mining process.

Working with stone cutting wire saw machines requires strict adherence to safety precautions to prevent accidents and injuries. Before operating the machine, operators must receive proper training on its usage and familiarize themselves with the safety features. Personal protective equipment, such as goggles, gloves, and ear protection, should be worn at all times to minimize risks. It is essential to ensure that the machine is in good working condition, with all safety guards and emergency stop buttons functioning properly.

During operation, operators must maintain a safe distance from the cutting area to avoid contact with the rotating diamond wire. The tension of the wire should be carefully adjusted to prevent snapping, which can cause serious injuries. Regular inspections and maintenance of the machine are crucial to identify potential hazards and rectify them promptly. By following these safety precautions, operators can safeguard themselves and their colleagues while maximizing productivity.

To ensure the longevity and optimal performance of a stone cutting wire saw machine, regular maintenance is essential. This includes cleaning the machine after each use, particularly removing debris from the wire assembly and inspecting for any signs of wear or damage. Lubrication of the moving parts is necessary to minimize friction and prolong their lifespan. Additionally, the diamond wire should be regularly replaced to maintain cutting efficiency.

In the event of any issues or malfunctions, troubleshooting steps should be followed to identify and resolve the problem. This may involve checking the power supply, wire tension, and control panel settings. If the issue persists, it is recommended to consult the machine's instruction manual or seek assistance from a qualified technician. Prompt troubleshooting and maintenance not only prevent costly downtime but also contribute to the safety and longevity of the machine.

In conclusion, stone cutting wire saw machines are vital tools in the mining industry, enabling efficient and precise extraction of stone blocks. By understanding the components and working principle of the machine, adhering to safety precautions, and conducting regular maintenance, operators can ensure their safe and effective usage. Proper knowledge and practices contribute to a productive mining process while prioritizing the well-being of the individuals involved.