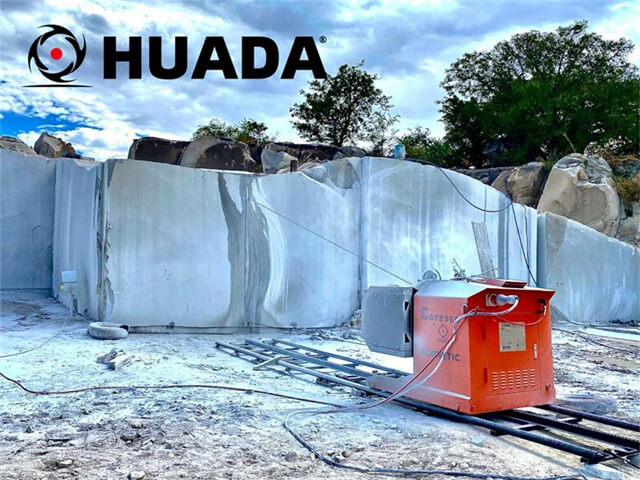

Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-07-24

Diamond wire rock cutting machines are widely used in mining and construction industries for their efficiency and precision. Regular maintenance is crucial to ensure the optimal performance and longevity of these machines. In this maintenance guide, we will discuss the key steps to maintain a diamond wire rock cutting machine.

Regular cleaning and lubrication are essential for the smooth operation of a diamond wire rock cutting machine. After each use, clean the machine thoroughly using a soft cloth and mild detergent. Remove any debris or dust that may have accumulated on the machine's surface. It is important to pay attention to the wire mechanism and ensure that it is free from any dirt or debris. Lubricate the wire mechanism and other moving parts as per the manufacturer's instructions to minimize friction and maximize efficiency.

Periodic inspection is crucial to identify any wear and tear or damage to the machine. Check the diamond wire regularly for signs of wear or damage. If any broken or worn-out sections are found, they should be replaced immediately to prevent further damage and ensure the safety of the operation. Additionally, inspect the machine’s electrical components, control panel, and safety features to ensure they are functioning correctly. Replace any faulty parts or components promptly to maintain the machine's optimal performance.

Proper calibration and alignment are essential for the accurate cutting performance of a diamond wire rock cutting machine. Periodically check the machine's calibration to ensure that it is aligned correctly and cutting accurately. If any deviations are observed, adjust the machine's settings as per the manufacturer's guidelines. Pay close attention to the tension of the diamond wire and ensure it is set according to the recommended specifications. Proper calibration and alignment not only enhance the machine's performance but also extend the lifespan of the diamond wire.

In conclusion, regular maintenance is vital for the optimal performance and longevity of diamond wire rock cutting machines. By following the cleaning and lubrication practices, conducting regular inspections and replacements, and ensuring proper calibration and alignment, you can maximize the efficiency and lifespan of your machine. Remember to always refer to the manufacturer's guidelines and seek professional assistance when necessary. With proper care and maintenance, your diamond wire rock cutting machine will continue to deliver outstanding results in your mining and construction projects.