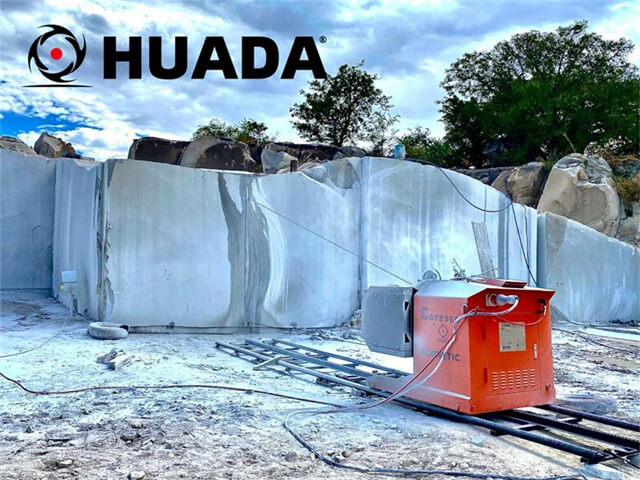

Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-07-24

The diamond wire saw machine is a versatile tool widely used in the granite industry. It offers numerous benefits and applications, making it an essential tool for granite cutting and shaping. This article will explore the versatile applications of the diamond wire saw machine for granite, highlighting its various uses and advantages.

One of the primary applications of the diamond wire saw machine is precise cutting of granite. The machine utilizes a thin diamond wire that moves in a continuous loop, allowing for accurate and clean cuts. The diamond wire's ability to cut through granite with precision makes it an ideal tool for various applications, such as creating customized kitchen countertops, intricate sculptures, and architectural elements.

The diamond wire saw machine's precise cutting capability ensures minimum material wastage, resulting in cost savings for granite manufacturers. Moreover, the machine's ability to cut granite into different shapes and sizes allows for the creation of unique and intricate designs, catering to the diverse needs of customers.

The diamond wire saw machine offers significant improvements in cutting efficiency compared to traditional cutting tools. The machine's continuous cutting motion reduces downtime and increases productivity, allowing for faster completion of projects. Additionally, the diamond wire's self-sharpening feature ensures a constant cutting performance throughout its lifespan, eliminating the need for frequent tool replacements.

Furthermore, the diamond wire saw machine can handle large volumes of granite cutting without compromising on quality. Its high-speed cutting ability enables granite manufacturers to meet tight deadlines and fulfill large-scale orders efficiently. The increased efficiency provided by the machine translates into improved productivity and profitability for businesses operating in the granite industry.

Another notable application of the diamond wire saw machine is its contribution to reducing the environmental impact of granite cutting. The machine utilizes water as a coolant, reducing dust and airborne particles during the cutting process. This feature not only improves working conditions but also minimizes the release of harmful pollutants into the environment.

In addition, the diamond wire saw machine's efficient use of resources, such as water and electricity, makes it an environmentally friendly choice. It consumes less water compared to traditional cutting tools, conserving this precious resource. Furthermore, the machine's high energy efficiency reduces carbon footprint, contributing to sustainable practices in the granite industry.

In summary, the diamond wire saw machine is a versatile tool that offers precise cutting, increased efficiency, and reduced environmental impact in the granite industry. Its ability to cut granite with accuracy and produce customized designs makes it invaluable for various applications. Additionally, its improved cutting efficiency and reduced environmental footprint contribute to the overall productivity and sustainability of granite manufacturing processes. The diamond wire saw machine continues to revolutionize granite cutting and shaping, enabling businesses in the industry to thrive while minimizing their environmental impact.