Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-07-12

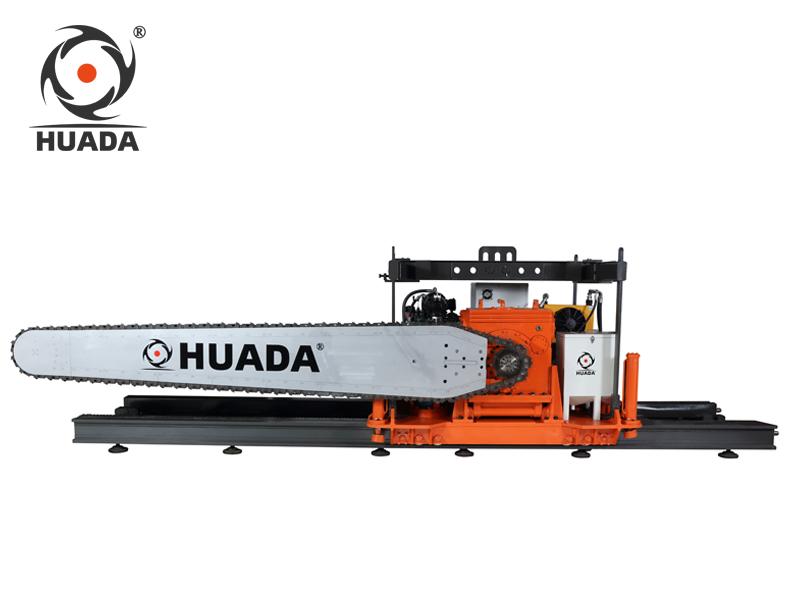

Quarry cutting machines play a vital role in the mining industry by efficiently extracting stone materials for various construction projects. However, like any other machinery, these machines require regular maintenance and care to ensure optimal performance and longevity. In this article, we will discuss the importance of quarry cutting machine maintenance and provide some key tips on how to effectively take care of these machines.

One of the essential aspects of maintaining quarry cutting machines is performing regular inspections and lubrication. Inspecting the machine's components, such as the blades, motors, hydraulic systems, and electrical connections, can help identify any signs of wear or damage. It is crucial to replace any worn-out parts promptly to prevent further damage and costly repairs.

Additionally, proper lubrication of the machine's moving parts is critical for ensuring smooth operation. Lubricating the bearings, chains, gears, and other moving components can significantly reduce friction and prevent premature wear. It is recommended to follow the manufacturer's guidelines regarding the type and frequency of lubrication required for each part.

Quarry cutting machines often operate in dusty environments, and the accumulation of dirt, dust, and debris can adversely affect their performance. Regular cleaning is essential to remove any build-up that can clog or obstruct the machine's moving parts and cooling systems.

Start by shutting down the machine and disconnecting it from the power source before cleaning. Use compressed air, brushes, or vacuum cleaners to remove dust and debris from the machine's exterior and interior components. Pay particular attention to the air filters, cooling fans, and ventilation ducts, as these are prone to clogging. Keeping these areas clean will allow the machine to operate at optimal temperatures, preventing overheating and potential damage.

The third crucial aspect of quarry cutting machine maintenance is operator training and adherence to safe practices. It is essential to ensure that all operators are adequately trained on the proper operation, handling, and maintenance of these machines. This includes understanding the machine's operating procedures, safety features, and emergency protocols.

Operators should also be educated about the limitations and capacity of the machine to prevent overloading or misuse. Regularly reminding operators to avoid excessive force or sudden movements can help minimize wear and tear on the machine's components.

Furthermore, encouraging operators to report any unusual sounds, vibrations, or performance issues during operation can help identify potential problems early on and avoid more significant damage.

In conclusion, proper maintenance and care of quarry cutting machines are vital for maximizing their efficiency, extending their lifespan, and reducing costly repairs. Regular inspections, lubrication, cleaning, and operator training are key aspects of effective machine maintenance. By following these guidelines, mining companies can ensure that their quarry cutting machines remain in optimal condition, leading to improved productivity and profitability in the mining industry.