Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-07-06

Efficient Usage Techniques of Granite Wire Saw Cutting Machine

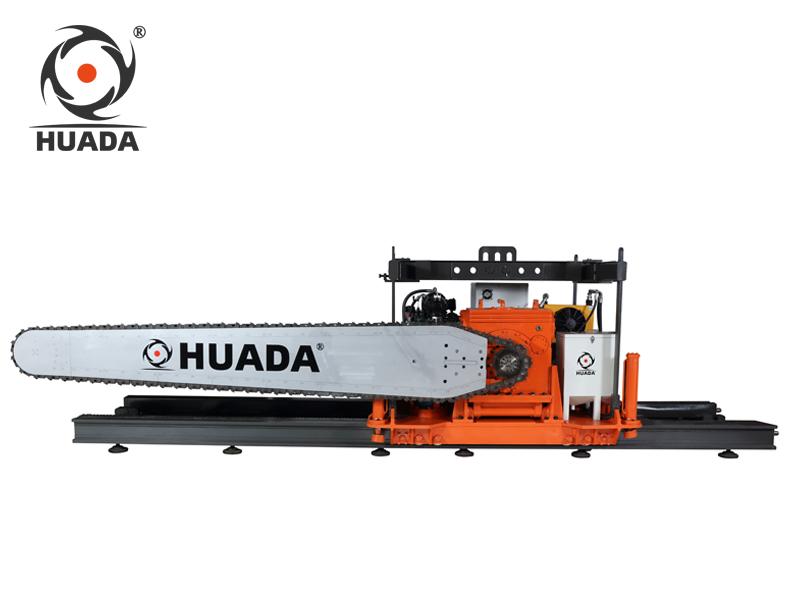

Granite is a popular and highly durable natural stone used for various applications, including countertops, flooring, and monuments. To extract granite from quarries and process it into desired shapes and sizes, the use of wire saw cutting machines has become increasingly common. This article aims to discuss efficient usage techniques for maximizing the productivity and effectiveness of granite wire saw cutting machines.

Regular maintenance and inspection of the wire saw cutting machine are crucial for its efficient operation. Firstly, it is essential to keep the machine clean and free from debris that may affect its performance. Regularly removing dirt, dust, and slurry from the machine will help prevent clogging and ensure smooth operation. Secondly, inspecting the machine's components, such as the diamond wire, hydraulic system, and tensioning system, is vital. Any signs of wear, damage, or misalignment should be addressed promptly to prevent further issues and ensure optimal cutting efficiency.

Adjusting cutting parameters according to the specific characteristics of the granite being processed is crucial for efficient usage of the wire saw cutting machine. Firstly, the cutting speed needs to be optimized. Increasing the cutting speed too much may result in reduced wire life and excessive tool wear, while decreasing it too much may prolong the cutting time unnecessarily. Secondly, the feed rate should be adjusted to ensure proper balance between productivity and precision. Too high of a feed rate may cause vibrations and inaccurate cuts, while too low of a rate may lead to inefficient progress. Additionally, the water flow rate and pressure should be adjusted to maintain effective cooling and lubrication during cutting, preventing overheating and improving wire longevity.

Beyond basic maintenance and parameter adjustments, there are advanced cutting techniques that can further enhance the efficiency of granite wire saw cutting machines. One such technique is the use of multiwire machines. These machines feature multiple diamond wires operating simultaneously, allowing for higher cutting speeds and increased productivity. Another technique is the implementation of computer numerical control (CNC) systems. CNC systems enable precise control and automation of the cutting process, reducing manual errors and maximizing efficiency. Additionally, using specialized diamond wires with improved durability and cutting performance can also greatly enhance the machine's efficiency.

Efficient usage of granite wire saw cutting machines is essential to optimize productivity, reduce costs, and achieve high-quality results. Regular maintenance and inspection, along with proper adjustments of cutting parameters, can significantly improve the machine's efficiency. Furthermore, implementing advanced cutting techniques, such as multiwire machines and CNC systems, can further enhance productivity and precision. By employing these techniques, operators can maximize their output while minimizing downtime, ultimately benefiting both the quarrying industry and end-users of granite products.