Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-08-09

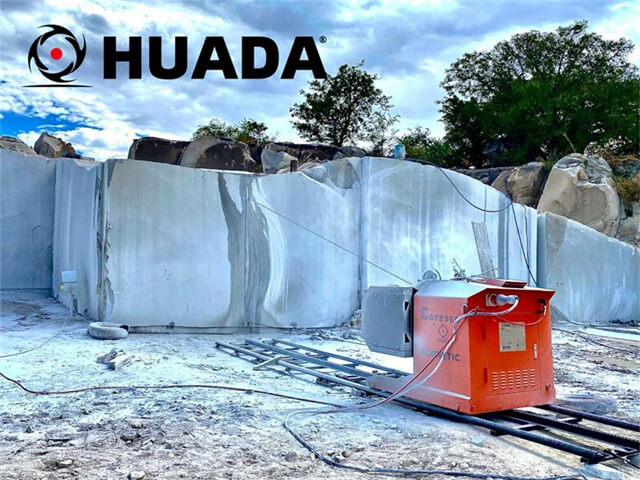

The wire saw machine is an essential tool in the stone mining industry. It is widely used for cutting and shaping various types of stones. To ensure its optimal performance and longevity, regular maintenance is crucial. In this article, we will provide some useful tips for maintaining a wire saw machine.

Regular cleaning and lubrication are essential for the proper functioning of a wire saw machine. After every use, make sure to remove any debris or slurry from the machine. Use a brush and water to clean the wire, pulleys, and guide rollers. This will prevent the accumulation of dirt and prolong the lifespan of the wire.

Additionally, apply lubricant to the guide rollers and pulleys to reduce friction. This will not only improve the cutting efficiency but also prevent wear and tear on these components. Remember to follow the manufacturer's instructions regarding the type and frequency of lubrication.

Regular inspection is essential to identify any potential issues and address them promptly. Inspect the wire saw machine thoroughly, checking for loose bolts, damaged wires, and worn-out components. Replace any faulty or worn-out parts to avoid further damage to the machine and ensure safety during operation.

Pay close attention to the tension of the wire. Improper tension can lead to uneven cuts and increase the risk of wire breakage. Use a tension gauge to measure the tension regularly and adjust it if necessary. Proper tension will ensure precise cutting and extend the life of the wire.

Proper training of operators is crucial for the safe and efficient operation of a wire saw machine. Make sure that all operators are adequately trained on the correct operation procedures, including safety precautions. This will minimize the risk of accidents and machine damage.

Provide operators with personal protective equipment, such as gloves, safety glasses, and ear protection. Encourage them to use these protective measures consistently to prevent injuries. Regularly remind operators of the importance of following safety guidelines, including proper handling of the machine and adhering to recommended cutting parameters.

In conclusion, regular maintenance is essential for the optimal performance and longevity of a wire saw machine. By following these maintenance tips, including cleaning and lubrication, regular inspection, and operator training, you can ensure smooth operation, minimize downtime, and maximize the lifespan of your wire saw machine.