Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-07-30

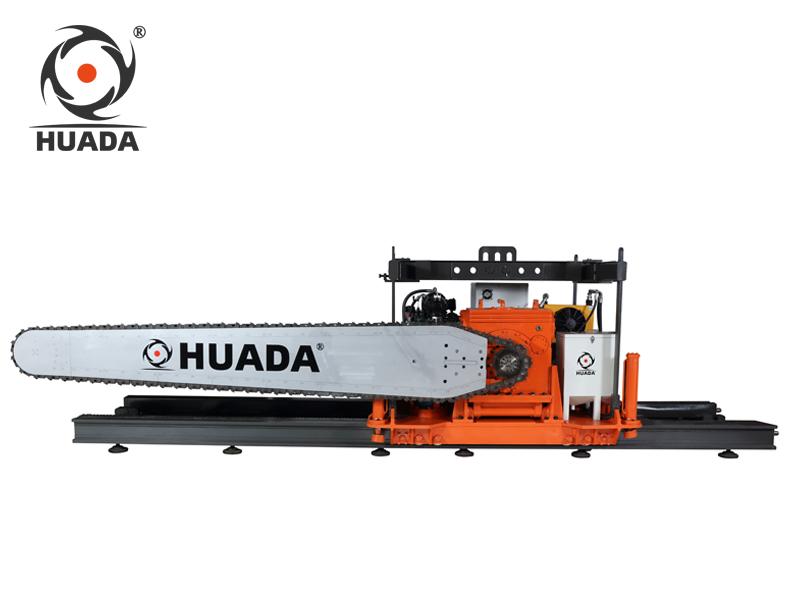

Stone quarry cutting machines are essential equipment in the mining industry. They play a crucial role in extracting, cutting, and processing stone materials. However, like any other machinery, these machines require regular maintenance and care to ensure optimal performance and longevity. In this article, we will explore some important maintenance and care practices for stone quarry cutting machines.

Regular inspection and cleaning are vital for ensuring the smooth operation of stone quarry cutting machines. Inspect the machine thoroughly, checking for any signs of wear, damage, or loose parts. Pay close attention to the cutting blades, motor, hydraulic system, and electrical connections. Clean the machine regularly, removing any dust, dirt, or debris that may accumulate during the mining process. Use appropriate cleaning agents and tools to prevent damage to the machine components.

Lubrication is essential to reduce friction and prevent excessive wear on moving parts of the stone quarry cutting machine. Follow the manufacturer's guidelines to determine the appropriate lubricants for different components. Regularly lubricate the cutting blades, bearings, chains, and gears to ensure smooth movement. Additionally, pay attention to the hydraulic system and check for any leaks or malfunctions. Maintain the hydraulic fluid levels and replace them when necessary.

The cutting blades of the stone quarry cutting machine are subjected to high levels of stress and wear. Dull or damaged blades not only reduce productivity but also increase the risk of accidents. Regularly inspect the blades and sharpen them as needed. Follow the manufacturer's instructions for proper blade sharpening techniques. When the blades become excessively worn or damaged, replace them with new ones to ensure efficient cutting and minimize downtime.

In conclusion, proper maintenance and care are crucial for stone quarry cutting machines to perform at their best. Regular inspection, cleaning, lubrication, and hydraulic system maintenance are essential practices to ensure smooth operation and longevity. Additionally, blade sharpening and replacement are necessary to maintain efficient cutting and productivity. By following these maintenance and care practices, stone quarry operators can optimize the performance of their machines and maximize their investment.