Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-07-26

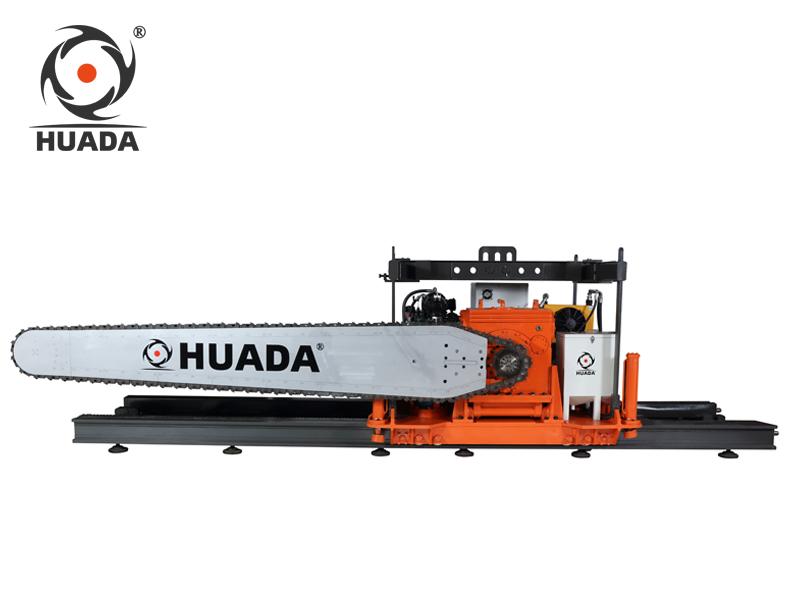

The efficient usage of stone quarry cutting machines plays a crucial role in the mining industry. These machines are designed to extract large blocks of natural stone with precision and speed, making them essential tools for quarry operators. By optimizing the use of these cutting machines, quarries can maximize productivity, minimize waste, and improve overall operational efficiency.

One of the key advantages of stone quarry cutting machines is their ability to perform precise cuts. These machines utilize advanced technology such as diamond wire saws or diamond-tipped blades to slice through the stone with accuracy. This level of precision ensures that the extracted blocks have smooth surfaces and exact dimensions, reducing the need for additional processing and saving time and resources.

Furthermore, some cutting machines are equipped with computerized control systems that allow operators to program specific cutting patterns. This feature enables the machines to follow predetermined paths, resulting in consistent and uniform cuts across multiple stones. By utilizing this advanced technology, quarries can minimize material wastage and optimize the extraction process.

The efficient usage of stone quarry cutting machines also contributes to improved workflows and increased productivity. These machines are designed to handle heavy workloads and operate continuously for extended periods. They can cut through various types of rocks and stones, including granite, marble, limestone, and more, making them versatile in different quarry environments.

By using these cutting machines strategically, quarries can streamline their operations and achieve faster production rates. For example, operators can plan the cutting sequence based on the geological characteristics of the quarry to optimize the utilization of the machine. Additionally, the ability of these machines to cut multiple blocks simultaneously further enhances productivity, as it reduces the downtime between cuts and maximizes output.

Stone quarry cutting machines provide a safer and less labor-intensive alternative to traditional mining methods. With automated systems and advanced safety features, these machines minimize the risks associated with manual handling and reduce the dependence on human operators in hazardous environments.

For instance, some cutting machines incorporate sensors that detect any irregularities or obstructions during the cutting process. In case of such incidents, the machine automatically stops, preventing accidents and damage to both the equipment and personnel. Moreover, the use of remote-controlled systems allows operators to control the machines from a safe distance, reducing their exposure to potential hazards.

Furthermore, the adoption of stone quarry cutting machines reduces the need for excessive manual labor. Instead of relying solely on manual laborers to extract and process stones, quarries can assign their workforce to more skilled tasks, such as quality control or maintenance. This shift in labor allocation improves overall operational efficiency and creates a safer working environment.

In conclusion, the efficient usage of stone quarry cutting machines brings numerous benefits to the mining industry. By incorporating advanced technology, optimizing workflows, and enhancing safety, quarries can achieve higher productivity, minimize waste, and reduce labor intensity. As the demand for natural stone continues to rise, the effective utilization of these cutting machines becomes increasingly crucial for the sustainable growth of the industry.