Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-07-24

Introduction:

Diamond wire is a versatile tool with various applications in the granite industry. It has revolutionized the cutting and shaping processes, providing efficient and precise results. This article aims to explore the multiple uses of diamond wire for granite and highlight its benefits in different applications.

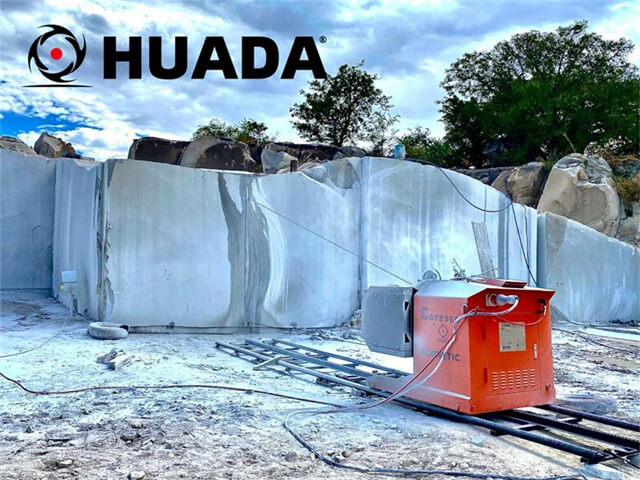

Diamond wire plays a vital role in quarrying and extraction of granite. It offers a cost-effective and time-efficient method for cutting through the hard rock formations. The diamond beads, embedded on the wire, possess exceptional cutting abilities due to their hardness. As the wire moves through the granite, these diamond beads grind away the material, allowing for smooth and accurate cutting. The use of diamond wire in quarrying reduces the noise, vibration, and dust levels compared to traditional methods, making it an environmentally friendly option.

Block sawing is a crucial step in granite processing, where large blocks are cut into slabs of desired thickness. Diamond wire saws have become the preferred choice for this task due to their efficiency and precision. The thin diamond wire can make precise cuts, minimizing material wastage and maximizing slab yield. Moreover, the wire's flexibility allows cutting complex shapes and curves, opening up new design possibilities for architects and designers. The block sawing process with diamond wire also reduces the labor required, resulting in cost savings for granite manufacturers.

Diamond wire finds extensive use in shaping and profiling granite materials. Whether it is creating intricate patterns, curved edges, or custom designs, the wire provides excellent control and accuracy. With diamond wire saws, fabricators can achieve smooth and precise cuts, ensuring a high-quality finish. This versatility allows for endless design options, making diamond wire an essential tool for sculptors and craftsmen who work with granite. The ease of use and precise shaping capabilities of diamond wire contribute to reducing production time and enhancing the overall efficiency of granite processing.

Conclusion:

In conclusion, diamond wire has become a cornerstone in the granite industry due to its versatility and exceptional performance. From quarrying and extraction to block sawing and shaping, it offers numerous advantages over traditional methods. The precision, efficiency, and reduced environmental impact make diamond wire an indispensable tool for professionals working with granite. As technology continues to advance, we can expect further innovations in diamond wire technology, leading to even more versatile applications and improved productivity in the granite sector.