Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-07-10

Maintenance and Care for Double Blade Cutting Machine

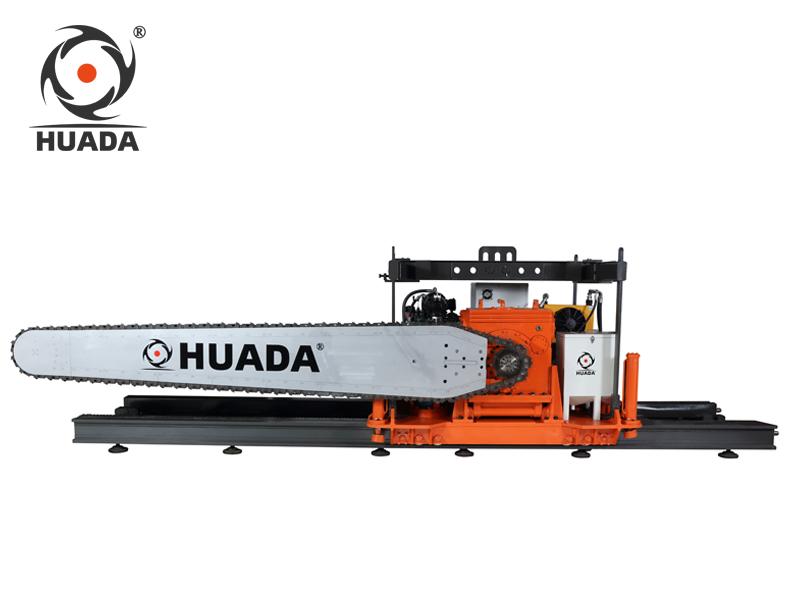

Double blade cutting machines are widely used in the mining industry for extracting and processing various types of stone materials. Proper maintenance and care are essential to ensure the longevity and efficiency of these machines. This article provides an overview of the maintenance and care practices required for double blade cutting machines.

Regular inspection and cleaning of the double blade cutting machine are crucial for its optimal performance. The machine should be inspected daily, looking for any signs of wear or damage. All moving parts, such as the blades, motors, and belts, should be examined for proper functioning. Any loose or damaged parts should be repaired or replaced immediately. Additionally, the machine should be cleaned regularly to remove any accumulated debris or dust that may affect its operation. Use a soft brush or compressed air to clean hard-to-reach areas.

Proper lubrication is essential for the smooth operation of the double blade cutting machine. Lubricate all moving parts according to the manufacturer's instructions. Pay special attention to the bearings, gears, and other components that require lubrication. Regularly check the oil levels and make sure they are within the recommended range. If necessary, replace the lubricant to prevent damage to the machine. In addition to lubrication, regular maintenance of moving parts is important. This includes adjusting belts, tightening screws, and ensuring proper alignment of the blades.

Safety should always be a top priority when operating a double blade cutting machine. Follow all safety guidelines and procedures provided by the manufacturer. Ensure that operators are trained on proper machine operation and safety protocols. Protective gear, such as gloves, goggles, and ear protection, should be worn at all times. Regularly inspect safety features, such as emergency stop buttons and safety guards, to ensure they are functioning correctly. Establish a regular schedule for safety inspections and maintenance.

In conclusion, the maintenance and care of double blade cutting machines are crucial for their efficient and safe operation. Regular inspection, cleaning, lubrication, and maintenance of moving parts are essential practices to ensure the longevity of the machine. Additionally, following safety measures and guidelines will help prevent accidents and injuries. By implementing these maintenance and care practices, operators can maximize the lifespan of the double blade cutting machine and maintain its optimal performance.