Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-07-10

Essential Product Knowledge for Quarry Cutting Machines

In the quarrying industry, one of the vital pieces of equipment is the cutting machine. These machines are used extensively to extract natural stone from quarries efficiently. To ensure optimal performance and safety, it is essential to have a comprehensive understanding of quarry cutting machines. This article will delve into the essential product knowledge required for operating these machines effectively.

There are various types of quarry cutting machines available in the market, each designed for specific purposes. Some common types include:

1. Wire Saw Machine: This type uses a wire with diamond beads to cut through the stone. It is particularly useful for cutting large blocks of stone with precision.

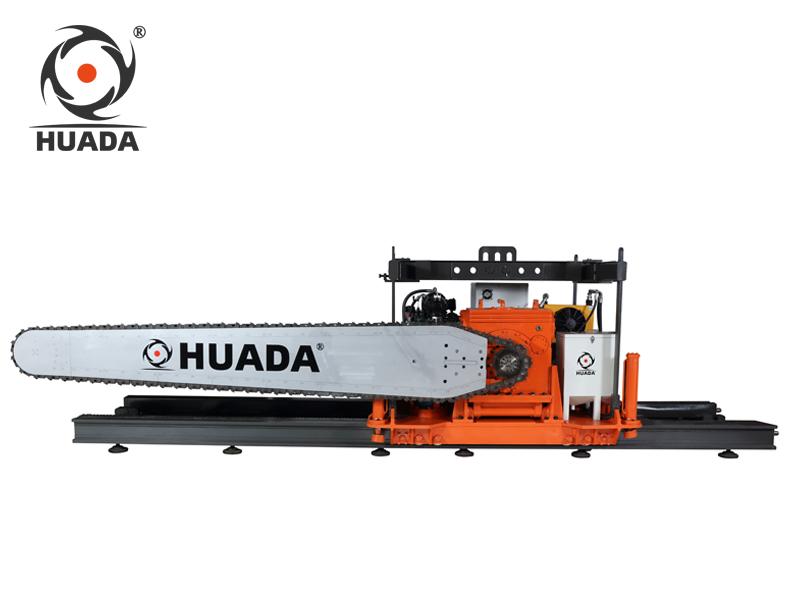

2. Chain Saw Machine: As the name suggests, this machine employs a chain with diamond teeth to slice through the stone. It is commonly used for quarrying softer stones.

3. Blade Cutting Machine: This machine utilizes a circular blade with diamond segments to cut through the stone. It is suitable for both horizontal and vertical cutting operations.

Operating a quarry cutting machine requires a thorough understanding of its principles and adherence to safety measures. Here are some important points to consider:

1. Training: Operators must receive proper training on machine operation, maintenance, and safety protocols before using the cutting machine.

2. Inspection: Before starting the machine, thorough inspection of all components and systems is necessary to ensure they are in good working condition.

3. Personal Protective Equipment (PPE): Operators should wear appropriate PPE, including safety goggles, gloves, and ear defenders, to protect themselves from potential hazards.

4. Machine Settings: Understanding the machine's speed, pressure, and cutting depth settings is crucial to achieve optimal cutting results and prevent damage to the machine or stone.

5. Regular Maintenance: Routine maintenance, such as blade sharpening, lubrication, and cleaning, should be performed to keep the machine in top condition and prevent unexpected breakdowns.

In conclusion, having a comprehensive understanding of quarry cutting machines is vital for efficient and safe operations in the stone extraction process. Knowing the different types of machines available, their operating principles, and implementing necessary safety measures can help maximize productivity while minimizing the risk of accidents. With proper training and consistent adherence to maintenance routines, quarry cutting machines can become invaluable assets in the quarrying industry.