Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-07-10

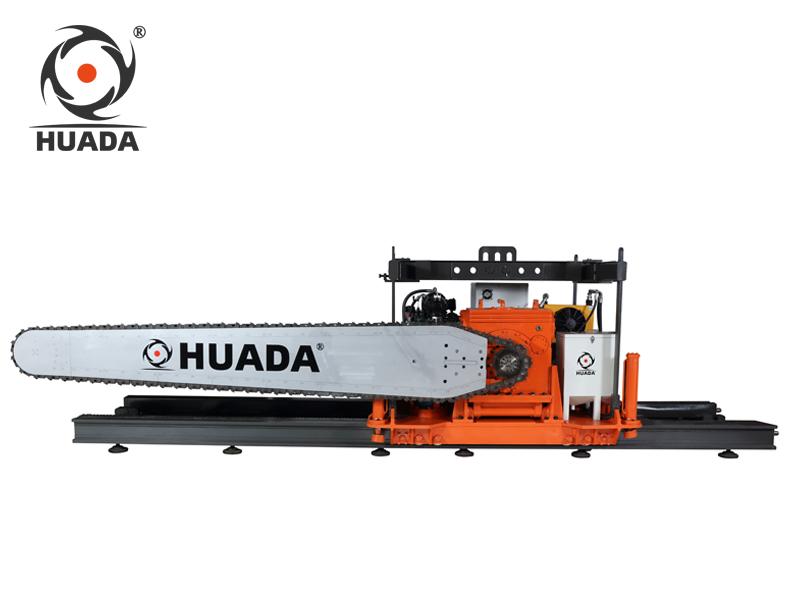

Double saw blade cutting machine is an essential tool used in the process of stone mining. This machine has revolutionized the way stones are extracted and processed, making it faster and more efficient. In this article, we will provide essential product knowledge for using a double saw blade cutting machine, including its components, working principle, and maintenance.

The double saw blade cutting machine consists of several key components that work together to ensure smooth and precise cutting of stone. These components include:

The double saw blade cutting machine operates based on a simple yet effective principle. When the machine is turned on, the motor drives the rotation of the saw blades. The stone to be cut is placed on the cutting table, and the operator adjusts the desired cutting parameters on the control panel. As the stone moves forward on the table, the rotating saw blades cut through the material, resulting in the desired shape or size.

It is important to note that the operator must ensure proper alignment of the stone with the saw blades to achieve accurate cutting. Additionally, safety precautions, such as wearing protective gear and maintaining a safe distance from the machine, should always be followed.

To ensure the optimal performance and longevity of the double saw blade cutting machine, regular maintenance is essential. Here are some key maintenance tasks:

In conclusion, understanding the essential product knowledge for using a double saw blade cutting machine is crucial for efficient and safe stone mining operations. Familiarizing oneself with the machine's components, working principle, and maintenance requirements can help operators optimize its performance and prolong its lifespan.