The use of hard rock cutting machines has revolutionized the process of stone excavation and mining. These machines are specifically designed to cut through tough rock formations, making them an indispensable tool in the mining and construction industries. With their advanced technology and efficiency, hard rock cutting machines have numerous applications and offer significant advantages over traditional methods.

Applications of Hard Rock Cutting Machines

Hard rock cutting machines find extensive applications in various industries, including:

-

Mining: Hard rock cutting machines are widely used in mining operations for excavating minerals such as coal, gold, iron ore, and diamonds. These machines can quickly penetrate and extract valuable resources from hard rock formations, increasing productivity and reducing manual labor.

-

Tunneling: Excavating tunnels through tough rock formations is a challenging task. Hard rock cutting machines make tunneling easier and faster by efficiently cutting through the rock. They are extensively used in the construction of transportation tunnels, water supply tunnels, and underground storage facilities.

-

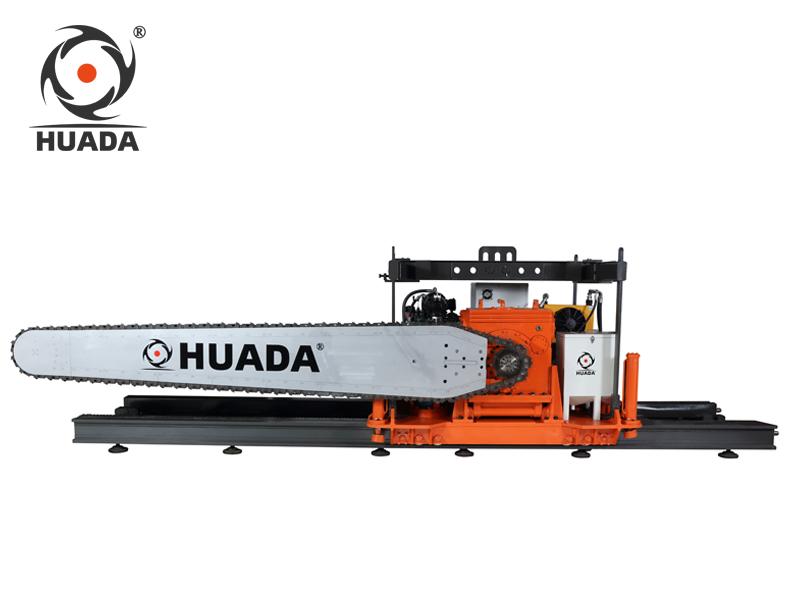

Quarrying: In the stone quarrying industry, hard rock cutting machines have become essential equipment. They are used to extract large blocks of stone from quarries with precision and speed. These machines not only enhance productivity but also minimize damage to the extracted stone, ensuring high-quality output.

Advantages of Hard Rock Cutting Machines

Hard rock cutting machines offer several advantages compared to traditional stone excavation methods:

-

Increased Efficiency: These machines can work continuously without the need for frequent breaks, resulting in higher productivity and shorter project completion times.

-

Reduced Labor Costs: By automating the cutting process, hard rock cutting machines significantly reduce the need for manual labor. This not only saves costs but also eliminates the risks associated with manual stone excavation.

-

Precision and Accuracy: Hard rock cutting machines use advanced cutting tools and technology to achieve precise and accurate cuts. This ensures minimal wastage and improves the overall quality of the extracted stone.

-

Enhanced Safety: Compared to traditional methods that involve manual drilling and blasting, hard rock cutting machines offer a safer working environment. They eliminate the risks associated with explosives, reduce dust generation, and minimize worker exposure to hazardous conditions.

Conclusion

The advent of hard rock cutting machines has transformed the stone excavation and mining industry. Their wide range of applications, including mining, tunneling, and quarrying, showcases their versatility and effectiveness. Moreover, the advantages they offer, such as increased efficiency, reduced labor costs, precision, and enhanced safety, make them an invaluable asset for any project involving hard rock excavation. As technology continues to advance, we can expect even more innovative designs and functionalities from hard rock cutting machines, further improving the efficiency and profitability of stone extraction operations.