Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-07-17

Essential Product Knowledge for Diamond Wire Saw Cutting

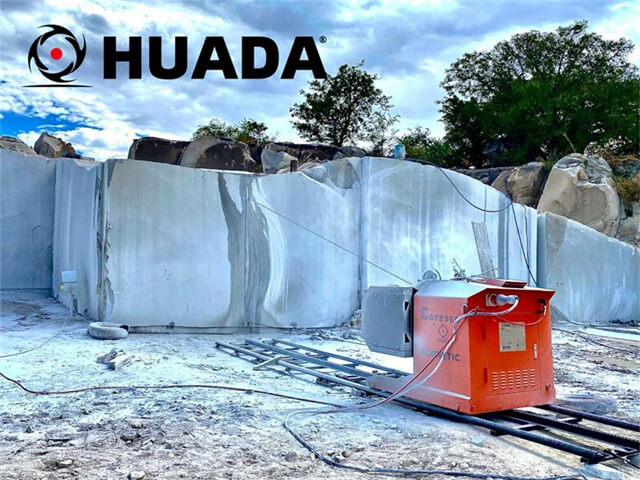

Diamond wire saw cutting is a widely used technique in various industries, including mining, construction, and stone processing. It offers precision cutting with minimal material wastage. However, to achieve optimal results and ensure safety, it is crucial to have a solid understanding of the essential product knowledge related to diamond wire saw cutting. This article aims to provide an overview of the key aspects that professionals should consider when using diamond wire saws.

Choosing the right wire for a diamond wire saw is of utmost importance as it significantly affects the cutting performance. There are several factors to consider when selecting a wire, such as diameter, diamond grit size, and bond type. The wire diameter determines the cutting speed and stability, with thicker wires offering higher stability but slower cutting speeds. Diamond grit size influences the wire's ability to cut different materials, with finer grit sizes suitable for harder materials. The bond type affects the wire's durability and lifespan. It is essential to choose a wire that matches the specific cutting requirements and the material being worked on.

Proper wire tensioning is critical for achieving accurate cuts and ensuring the wire's longevity. Over-tensioning or under-tensioning can lead to premature wear or breakage. Regular tension monitoring during operation is essential. Additionally, routine maintenance is necessary to prolong the wire's lifespan. This includes cleaning the wire after use to remove debris and lubricating it to reduce friction and heat generation. Inspecting the wire for any signs of damage, such as wear or cuts, is crucial to prevent accidents and maintain cutting efficiency.

Safety should always be a top priority when using diamond wire saws. Operators must wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and hearing protection. Adequate training on the correct use of the equipment is vital to minimize the risk of accidents. It is crucial to follow manufacturer guidelines and instructions for safe operation. Regularly inspecting the saw and its components, such as the wire, pulleys, and tensioning system, helps identify and address any potential hazards. Lastly, ensuring proper ventilation in the working area is important to mitigate the risks associated with dust and fumes generated during cutting.

Having a comprehensive understanding of essential product knowledge for diamond wire saw cutting is crucial for achieving optimal results and ensuring safety. Wire selection, including considering diameter, diamond grit size, and bond type, plays a significant role in determining cutting performance. Proper wire tensioning and regular maintenance are necessary to prolong the wire's lifespan and ensure accurate cuts. Lastly, prioritizing safety through the use of PPE, adequate training, and regular equipment inspections is paramount. By following these guidelines, professionals can maximize the effectiveness and efficiency of diamond wire saw cutting operations.