Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-07-12

In recent years, the utilization of diamond wire rock cutting machines has become increasingly popular in the mining industry. These machines offer immense efficiency and precision in extracting valuable stones from quarries and mines. In this article, we will explore the various benefits and techniques involved in utilizing diamond wire rock cutting machines effectively.

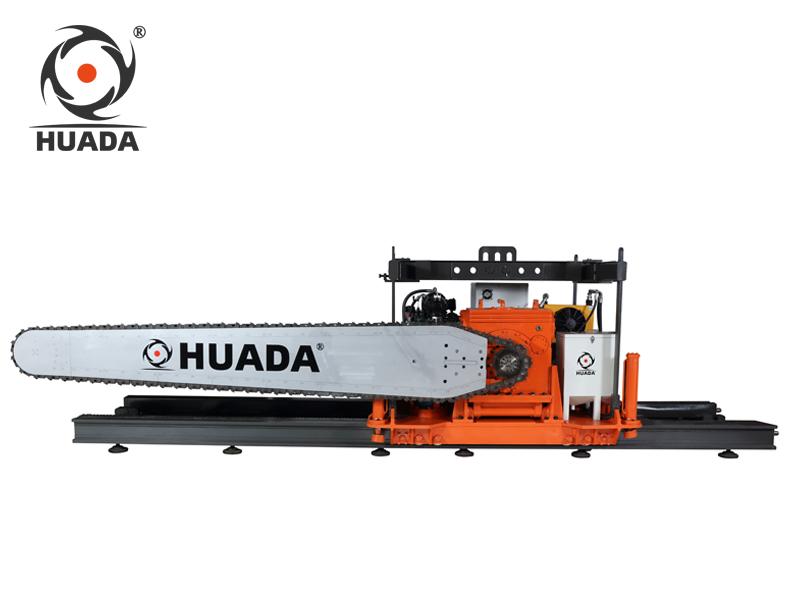

Diamond wire rock cutting machines have revolutionized the mining process by significantly improving efficiency and productivity. Unlike traditional methods, which rely on heavy machinery and explosives, diamond wire cutting machines use a thin, high-tensile wire embedded with industrial-grade diamonds. This wire is fed through the stone, making precise cuts and separating it from the surrounding rock.

The use of diamond wire cutting machines eliminates the need for drilling, blasting, and manual labor, resulting in faster extraction rates and higher productivity. Additionally, these machines are highly automated, reducing the risk of human error and increasing overall efficiency in the mining process.

Safety is of paramount importance in any mining operation, and diamond wire cutting machines contribute significantly to improving safety measures. Traditional mining methods involving explosives carry inherent risks, including accidents, injuries, and damage to the environment.

With diamond wire cutting machines, the need for explosives is eliminated, reducing the risk of accidents and creating a safer working environment. The machines are operated remotely, ensuring that workers are kept at a safe distance from the cutting process. Moreover, the precise and controlled nature of diamond wire cutting minimizes the chance of rock falls or collapses, further enhancing safety.

Diamond wire cutting machines not only offer improved efficiency and safety but also have significant cost advantages over traditional mining methods. The automated and precise nature of these machines reduces the overall labor costs associated with extraction. Moreover, the extraction process is faster, resulting in quicker turnover and increased revenue generation.

In addition to cost efficiency, diamond wire cutting machines have a lower environmental impact compared to traditional mining practices. The elimination of explosives minimizes air and noise pollution, making it an environmentally friendly choice. Furthermore, the precise cuts made by the machines minimize waste and ensure maximum utilization of the extracted stone, reducing overall ecological footprint.

In conclusion, the utilization of diamond wire rock cutting machines offers numerous benefits to the mining industry. Improved efficiency, enhanced safety measures, cost efficiency, and reduced environmental impact are some of the advantages associated with these machines. As technology continues to advance, the mining industry can expect further developments in diamond wire cutting technology, leading to even greater efficiency and sustainability in the future.